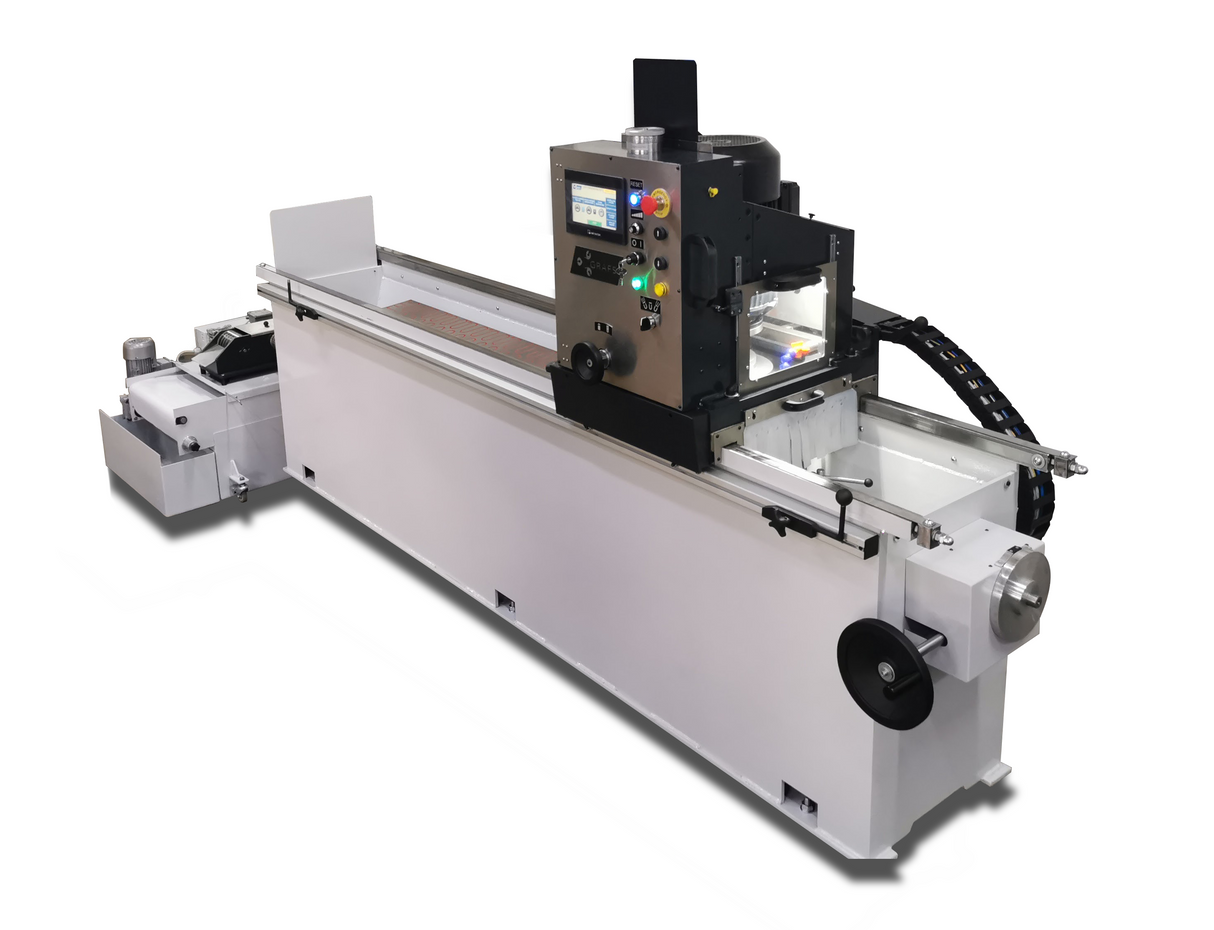

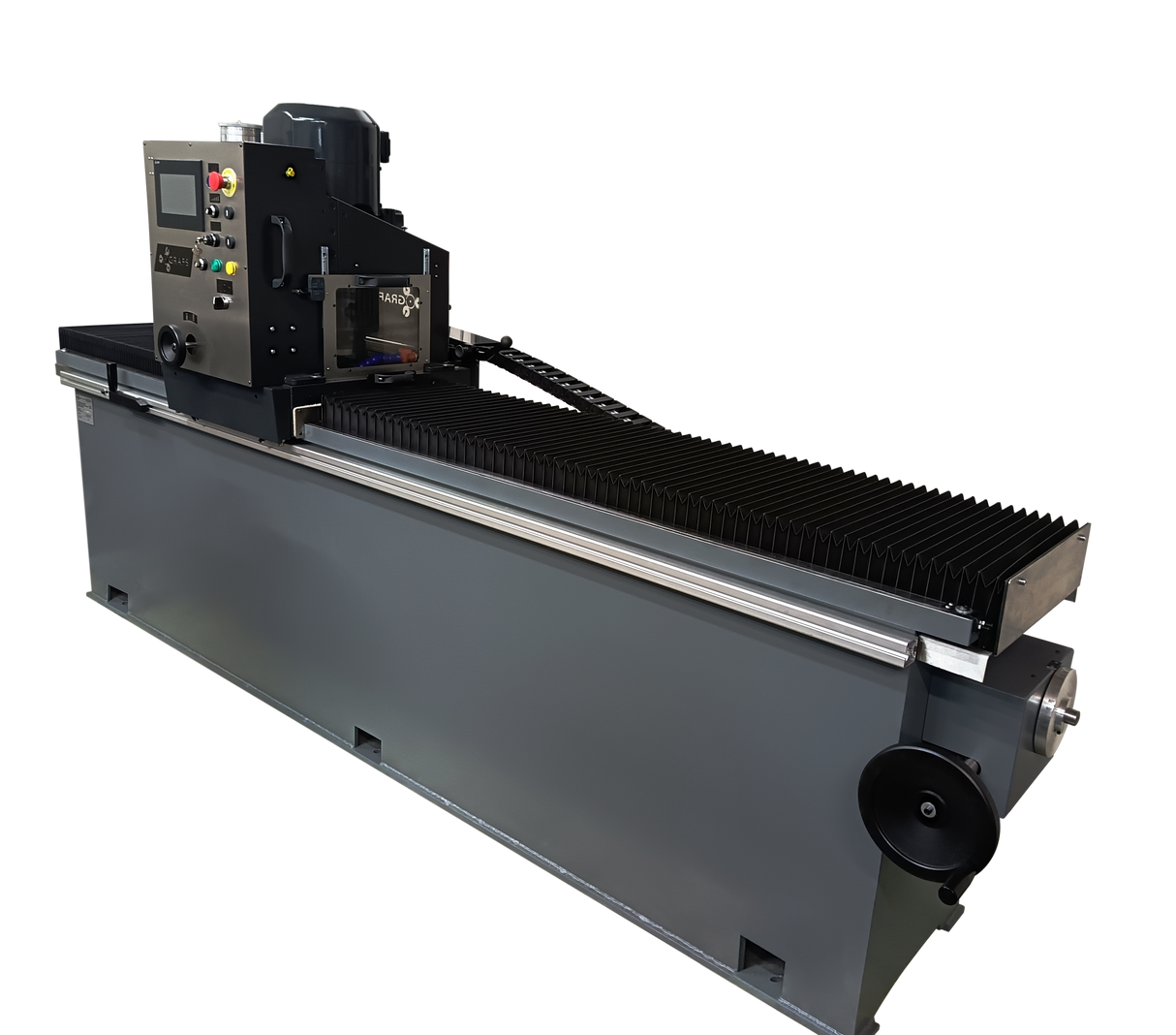

GRAFS GR industrial knife grinder – professional sharpening in the printing, woodworking and recycling industries

GRAFS GR series grinders are modern automatic machines designed for the precise sharpening of knives used in machines such as chippers, granulators, planers, guillotines, mills , and other devices requiring high rigidity and accuracy.

Thanks to its solid construction and European components, the GR model ensures reliable operation for many years even under intensive use.

Description

Description

The GRAFS GR series grinder is designed for sharpening knives used mainly in the printing, woodworking and recycling industries.

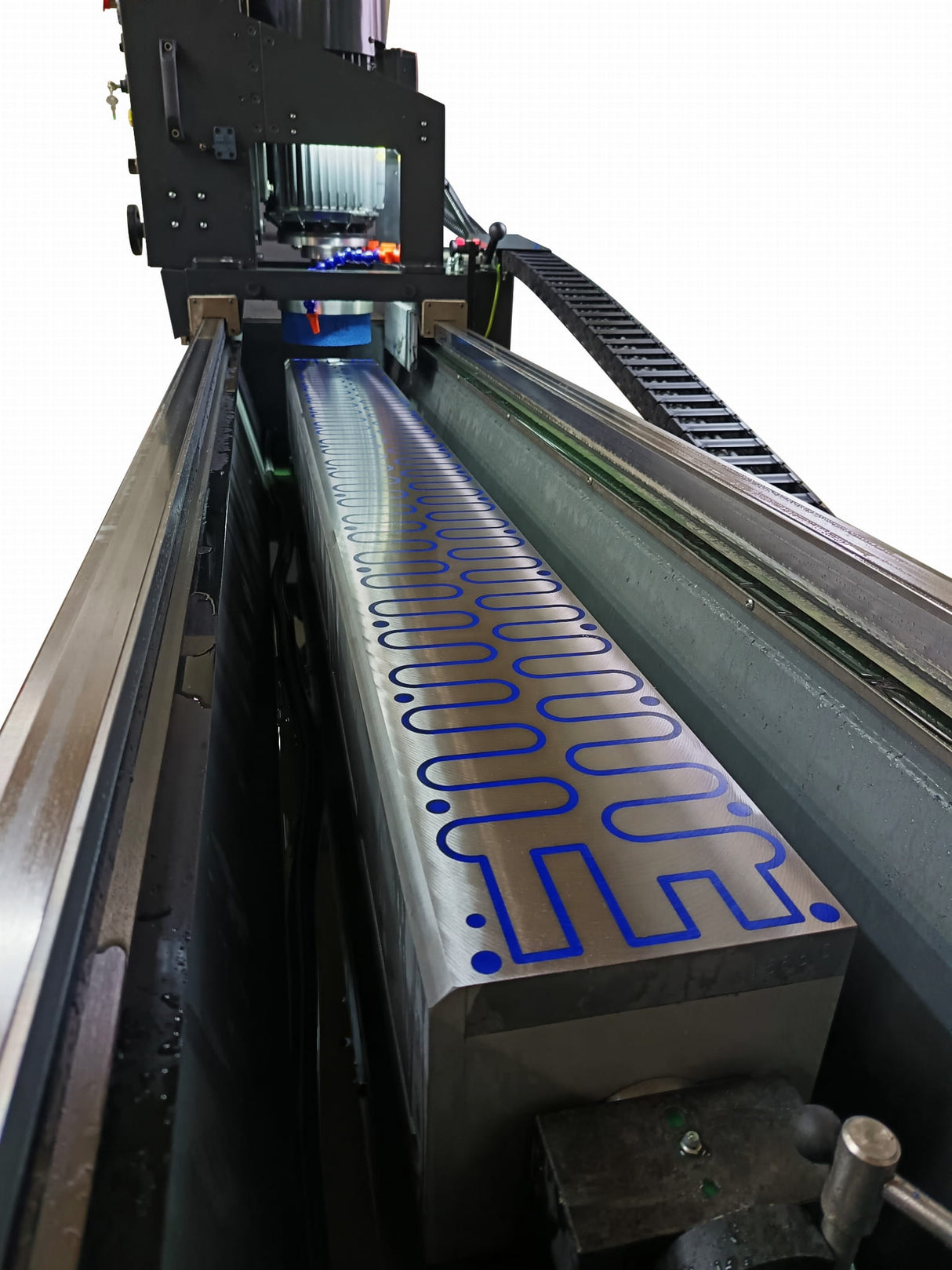

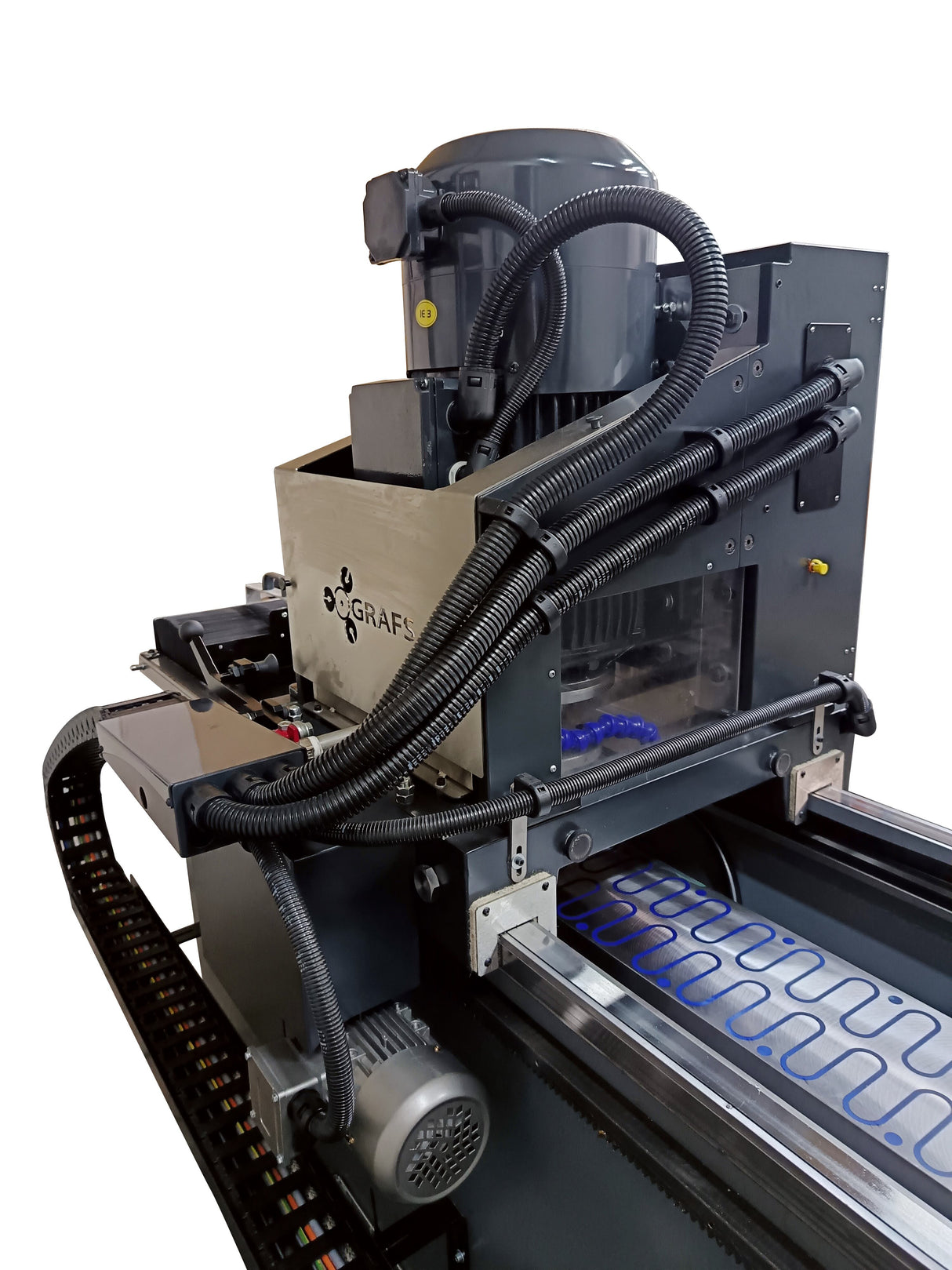

The grinder features a number of improvements that ensure high-quality sharpening for many years of use. It is equipped with a rotating electromagnetic chuck ( 1800 mm long in the GR-1800e model ), and knives can also be mounted using clamps on the other side of the table. Proper cooling of sharpened surfaces is ensured by a cooling system with a reservoir and a magnetic coolant separator with a rotating drum (model MS60).

The standard motor power of the grinder is 5.5 kW . Our special mounting bracket allows for quick and easy removal and installation of the grinding wheel using just three mounting screws.

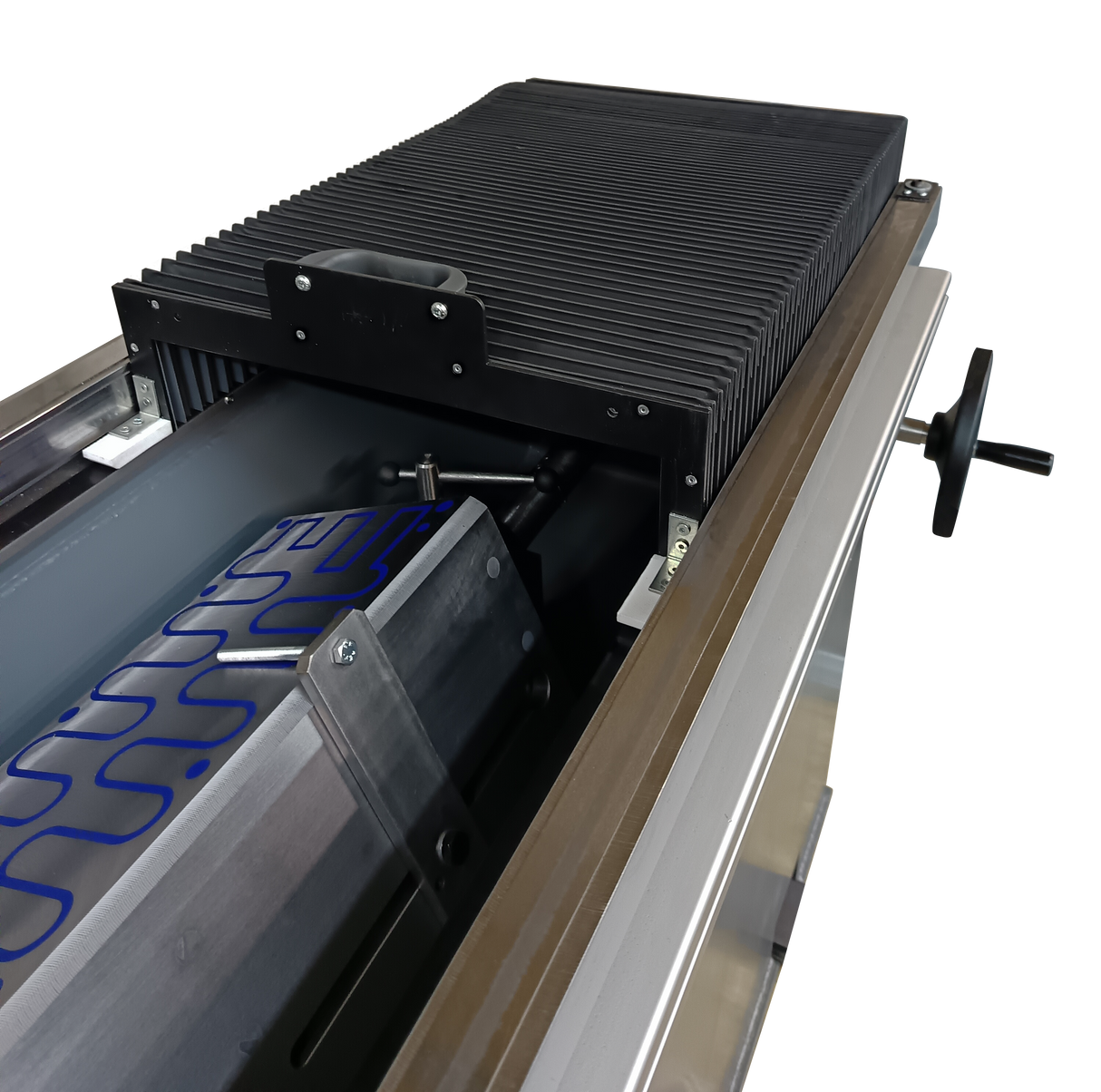

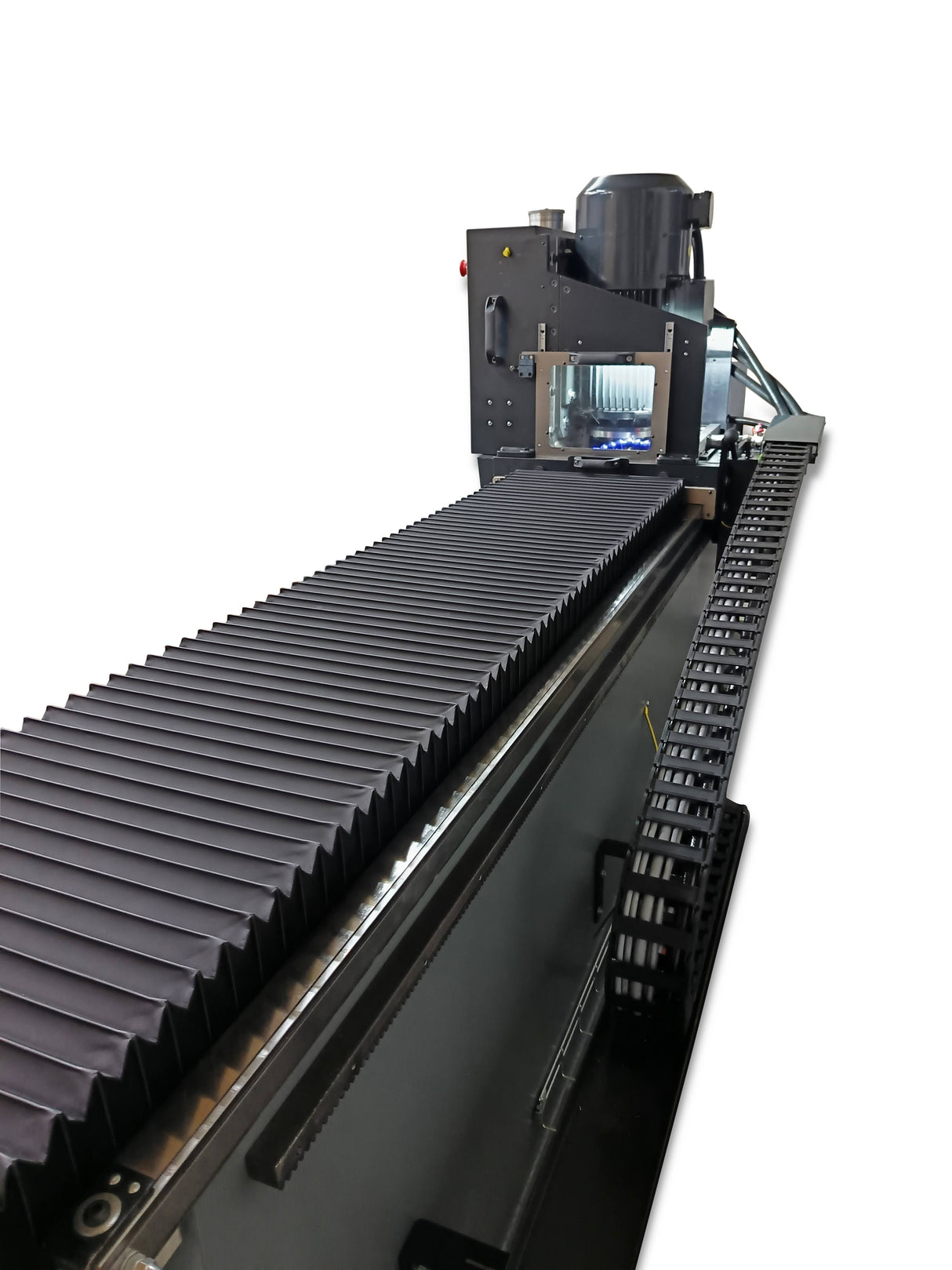

The trolley is equipped with top-quality rolling rollers (PWTR), ensuring quiet and smooth operation. The trolley runs on hardened steel belts.

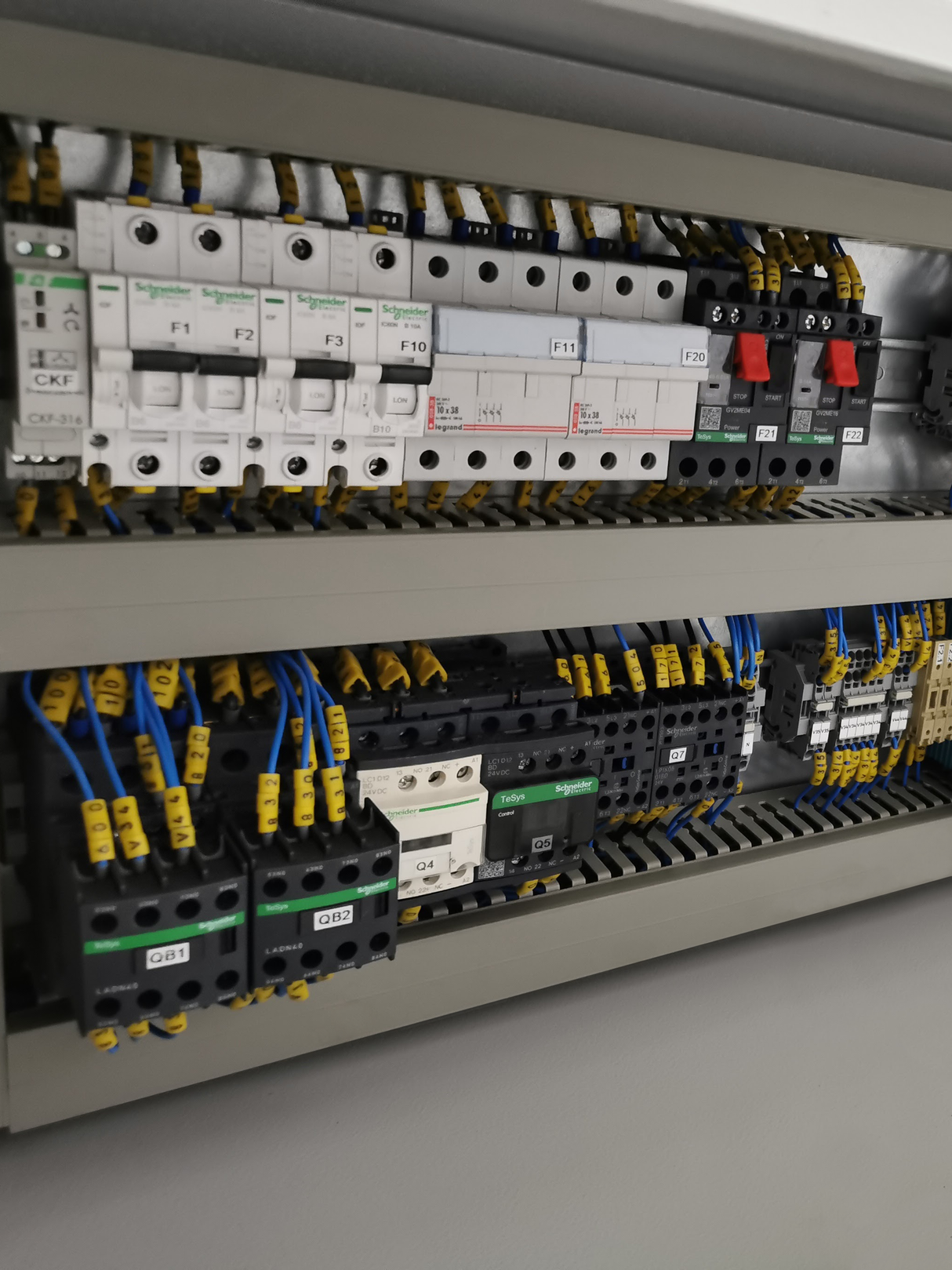

The GR model is additionally equipped with PLC control + 7″ HMI touch-screen panel from Mitsubishi , enabling easy programming of the sharpening process (various modes, i.e. operation without feed, grinding (automatic feed from 0.001 mm to 0.05 mm), sparking, pause), as well as remote service support via Wi-Fi.

The machine is ideal for sharpening knives that require high stiffness and precision , such as guillotine knives, recycling knives, granulators, large chippers, three-knife trimmers - wherever high efficiency and stability are required

Our solutions in the GRAFS GR machine:

- Easy-to-use 7-inch Mitsubishi HMI touch panel,

- Mitsubishi PLC controller, fully programmable operating modes: automatic feed in the range of 0.001 mm - 0.03 mm, automatic sparking, automatic machine shutdown after work is finished, electronic feed using a stepper motor. Parameter range can be changed before and during machine operation (number of passes, feed range),

- Module for communication with the machine via the Internet (remote service),

- Possibility to set the grinding wheel motor in an inclination position of 0-10 degrees , possibility of grinding surfaces , (special bumpers with adjustment screws for precise setting/adjustment of the motor in the "0" position)

- Tilting electromagnetic table , with a working surface of 150x1800 mm , 20 mm “S” type polarization, clamping force 120 N/cm2, table controlled from the main machine panel,

- Additional fastening with clamps on the other side of the table with a T-slot ,

- Replaceable hardened stainless steel tapes on the machine body guides,

- A mechanism allowing the carriage drive to be disconnected and the carriage to be manually positioned over the knife ,

- Possibility of moving the carriage relative to the carriage (in the Y axis) in order to sharpen knives of greater width (up to 350 mm),

- Quick up/down movement of the grinding wheel motor – for quick grinding wheel replacement,

- Possibility of adjusting the feed using the hand wheel and precise positioning of the grinding wheel motor in relation to the workpiece,

- Polish-made grinding wheel motor with a power of 5.5 kW, equipped with a holder allowing for quick replacement of any grinding wheel (including segmented whetstones) with a diameter in the range of 150-300 mm ,

- Special grinding wheel holder with 3 screws, allowing for quick removal and attachment of the grinding wheel,

- External coolant separator: MS60 magnetic separator, with a 150 L mobile tank and a 60 L/min pump,

- Carriage speed regulator 1-16 m/min (potentiometer + inverter),

- Scale indicating the motor feed,

- Scale indicating the table rotation angle,

- Coolant pipe inside the machine body (for table rinsing),

- 24V LED lighting of the workspace,

- User manual, diagrams, DTR in Polish,

- Painting: powder coated, body RAL7012, carriage RAL7021

ADDITIONAL OPTIONS:

- Possibility of mounting additional accordion covers on the machine body,

- Possibility to attach any coolant filter to the machine - magnetic, non-woven or a combined set.

The GR grinder is a 100% Polish product, built exclusively with European components. The machine has all the necessary electrical tests, a Polish manual, and an EU declaration of conformity (CE mark).

All major components for our machines are supplied by MITSUBISHI ELECTRIC.

GRAFS GR in detail

Fully automatic grinding machine for large chipper knives, planer knives, guillotine and paper cutter knives, recycling knives and blades

Add text to a video to showcase a detail of your brand or product line.

Comparison of knife grinder models

Are you looking for a knife grinder that will best meet the needs of your business?

We've prepared a practical comparison of GRAFS models to help you choose. You can check the length of the electromagnetic table, available grinding motors, and other technical parameters in one place.

This will allow you to quickly choose a machine that will ensure precise sharpening, high efficiency and many years of trouble-free operation in your industry – from printing to recycling and the woodworking industry.